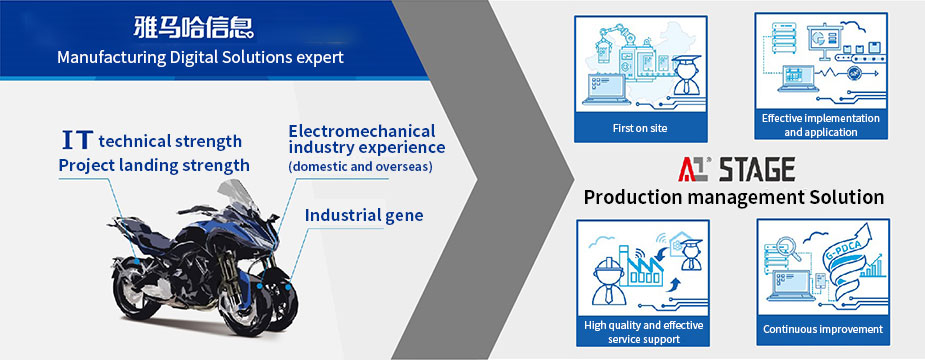

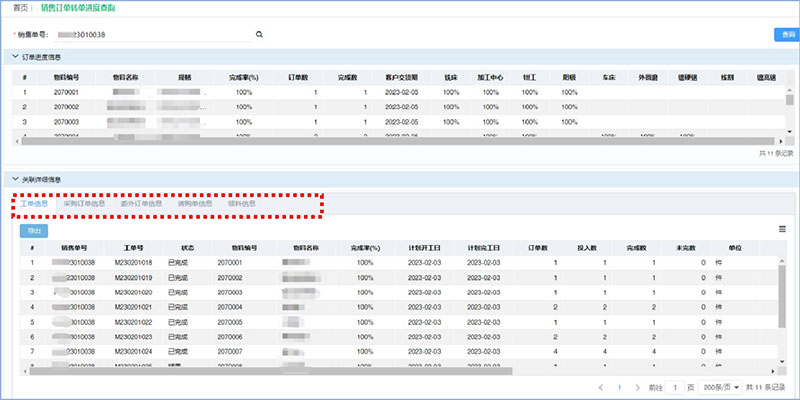

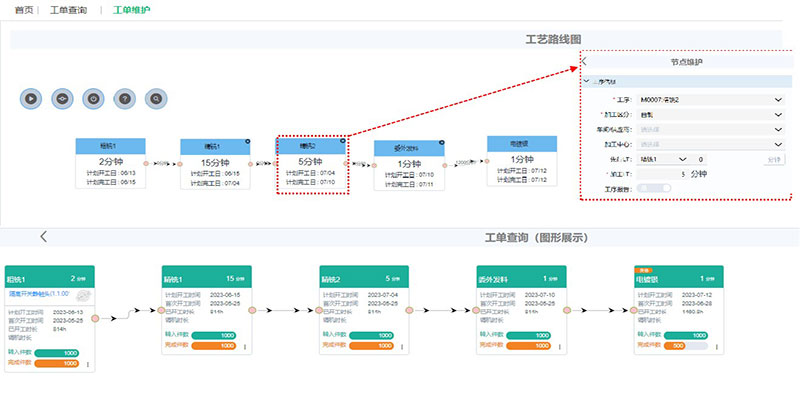

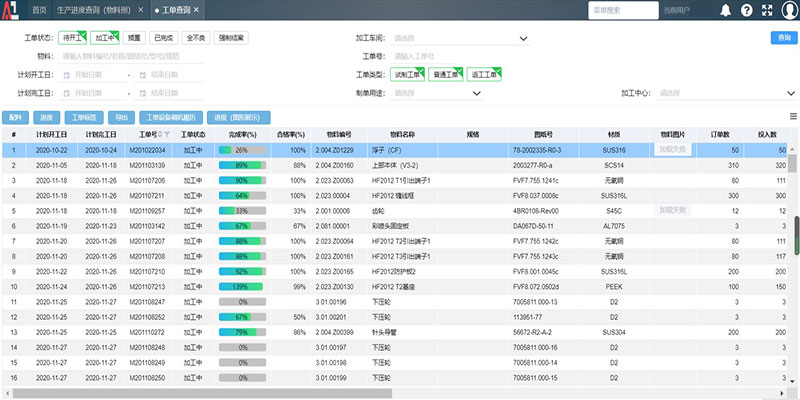

Yamaha Motor Solutions Co., Ltd. Xiamen focusing on the pain points of production manufacturing management in the component manufacturing industry, based on the production site, we provide forward-looking and vibrant one-stop information technology solutions and services for manufacturing customers in four aspects: production digitization, research and development digitization, marketing digitization, and administrative digitization. Using ERP, MES, and TOC management methods to assist enterprises in upgrading intelligent manufacturing, reducing communication costs, empowering production efficiency, and continuously enhancing brand strength and competitiveness.

0592-5652283

0592-5652283

Contact us

Contact us

Online message

Online message

Customer Service Hotline

Customer Service Hotline

Community:

Community: